Electrolube’s Alistair Little takes a closer look at some of the more ‘testing’ and technically probing questions that he receives from its customers in his latest blog on potting and encapsulation resins.

In my latest series of blogs for Electrolube, I have focussed on answering ‘five top tips’ for design engineers such as five common FAQ’s, and five design tips for harsh environments. This month my Blog has a bit of a ‘testing’ theme running through it, and I include my responses to more technically probing questions, such as: which resins are appropriate for RF applications; when can I use a single-, as opposed to a two-part resin; and when does the consistency of the resin’s dielectric constant become an important consideration? In no particular order, here are five questions from customers that raise a number of technical issues related to resin applications, together with my responses. Hopefully, it will provide useful background information to help you with your own problem-solving activities.

What weathering resistance tests does Electrolube carry out on its resin products, and how are the results of these tests translated into meaningful data that users can apply with confidence to real-world applications?

The easy question first then! How closely weathering test data relates to the real world has been exercising the minds of both the suppliers and users of resins since weathering tests were first developed. The main problem here is that a weathering (environmental and mechanical exposure) test rigs/regime will, at best, only cover two or three conditions, whereas in the real world things are far more complex and difficult to predict.

Testing is a fundamental process here at Electrolube. We carry out a range of thermal cycling (checking thermal shock resistance), water immersion, (fresh and salt) and chemical resistance, covering both atmospheric pollution as well as direct contact with corrosive or otherwise reactive substances. In addition, thermal stability checks are run at continuous operating temperatures and exposure to artificial daylight in order to determine the ultraviolet (UV) resistance/stability of the resin under test.

By combining the information gleaned from these tests, design engineers are able to select a resin that best fits their requirements. In many cases it is possible to input the results obtained into a model and undertake a FEMA study, where the environmental conditions are one consideration in predicting the long term performance of the final product. The results from the test conditions ensure that the user can expect optimal performance from Electrolube products in a range of environments.

Which industries typically ask for resins that are designed to perform well in RF applications, and what is so special about these resins?

Typically, the communications industry (manufacturers of mobile and fixed telecommunications equipment) is most likely to specify a resin that is specially formulated to protect electronic assemblies that generate radio frequency (RF) signals. These days, however, there are a lot of other companies that are now adding WiFi/Bluetooth functionality to a much wider range of products to facilitate easy communication between devices.

Resins designed for RF applications do not contain fillers – particles that might otherwise cause RF signal scattering or which attenuate the signal altogether. In many cases the transmission power of devices utilising WiFi/Bluetooth is quite low, so any intervening medium, such as a protective resin, which might reduce or scatter the signal strength, is a potential problem.

Flame retardancy is often specified for RF applications but most flame retardant resins will either contain halogens (which are now facing increasing regulatory restriction) or metal containing fillers (that scatter or attenuate RF signals). Electrolube has met this dilemma with its UR564/2/3 series of flame-retardant, filler-and halogen-free resins, which are suitable for a wide range of RF applications.

When is it important to ensure that a resin’s dielectric constant does not vary over the long term?

Dielectric constant (also known as relative permittivity) is an important parameter where resins are concerned. A low dielectric constant resin, for example, will have minimal impact on any electric field produced by a device and thus ensure maximum transparency for any signals generated by that device. It is also important that the resin’s dielectric constant remains low over the entire life of a product or system to which it has been applied. In the case of marine applications, for example, a resin’s consistent long-term electrical performance may be critical, as having to replace units compromised by dielectric constant variability is likely to be operationally costly, particularly if those units are in difficult-to-access areas, such as the bottom of the ocean.

How does Electrolube measure thermal conductivity and why is the accuracy of the testing method so important?

We have recently invested in some new thermal conductivity measurement equipment that uses the Modified Transient Plane Method of measuring thermal conductivity, (an improvement upon the well known Transient Plane Method, or Hot Disk), which has been well established over the years. This enables us to obtain a large number of measurements over a wide temperature range quickly and reliably.

Taking direct measurements of a thermal paste or cured resin provides values for thermal conductivity that are very close to those that would be experienced under real operating conditions; however, there will always be some slight variation due to the nature of the design of the unit and the components used. Unfortunately, there are still cases where the thermal conductivity of a cured resin will have been calculated from the component parts, rather than having been obtained from a measurement of the material. Calculated values are generally far higher than those obtained from direct measurement of the materials in question.

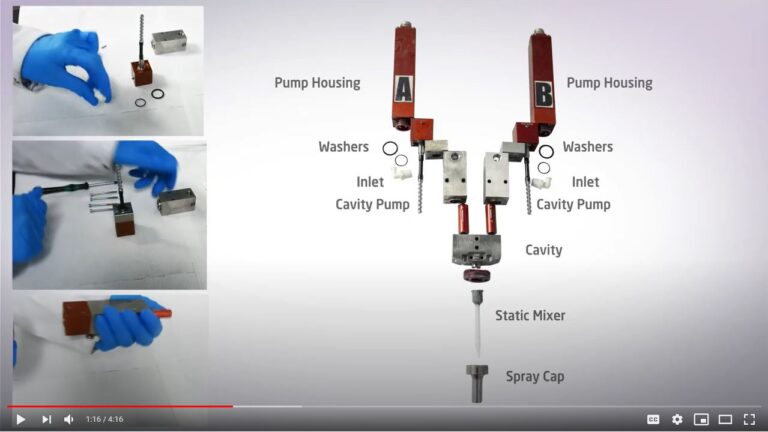

When is it appropriate to consider using a single-, as opposed to a two-component resin system?

Single component resins (or 1K resins) are generally used for adhesive applications, such as a glob top, or for bonding components to a PCB or other substrates. A 1K resin does have its disadvantages, however: viscosity is generally higher than that of its 2K counterpart, it requires an elevated cure temperature, will have a short shelf life and often need to be stored in a chilled environment. The main advantage of a 1K resin is its ease of application; no mixing is required and dispensing machine set up is a much simpler affair.

I hope this covers some useful points for you, remember to check back next month for the next instalment from my colleagues or myself or check back over our previous series.