Electrolube’s resins expert, Alistair Little, returns to the subject of potting and encapsulation resins with this Q&A guide to some of the problems you are likely to encounter, how to overcome them and what you need to know when selecting an appropriate material for your application.

When I last broached the subject of potting and encapsulation resins, I went into some depth on the subject, explaining their chemistries and physical properties, how they behave when being mixed, applied and cured. For this column, I’m going to return to our tried and trusted Q&A format, to offer four commonly asked questions about resins and their applications, together with my responses, which I hope will help you achieve the best outcomes for all your potting and encapsulation jobs. So, setting material choice aside for the moment, let’s start with a key aspect of potting: getting the resin in place.

What common problems are associated with the physical mechanics of potting?

There are several problems that you will encounter when applying a resin to pot a component or an enclosed area on a PCB. Two problems that frequently crop up, and which must be addressed if you are to avoid some basic problems are:

- Achievement of an even flow of resin within the volume to be potted, ensuring that all of the components within this volume are covered.

- Ensuring that there is minimal air entrapment within the resin, which often occurs if the flow is turbulent. Air bubbles formed in close proximity to the components are most undesirable as the heat transfer performance of the resin is compromised and component overheating is likely to occur. This could also create an area for chemicals to attack the component.

How do I avoid these problems?

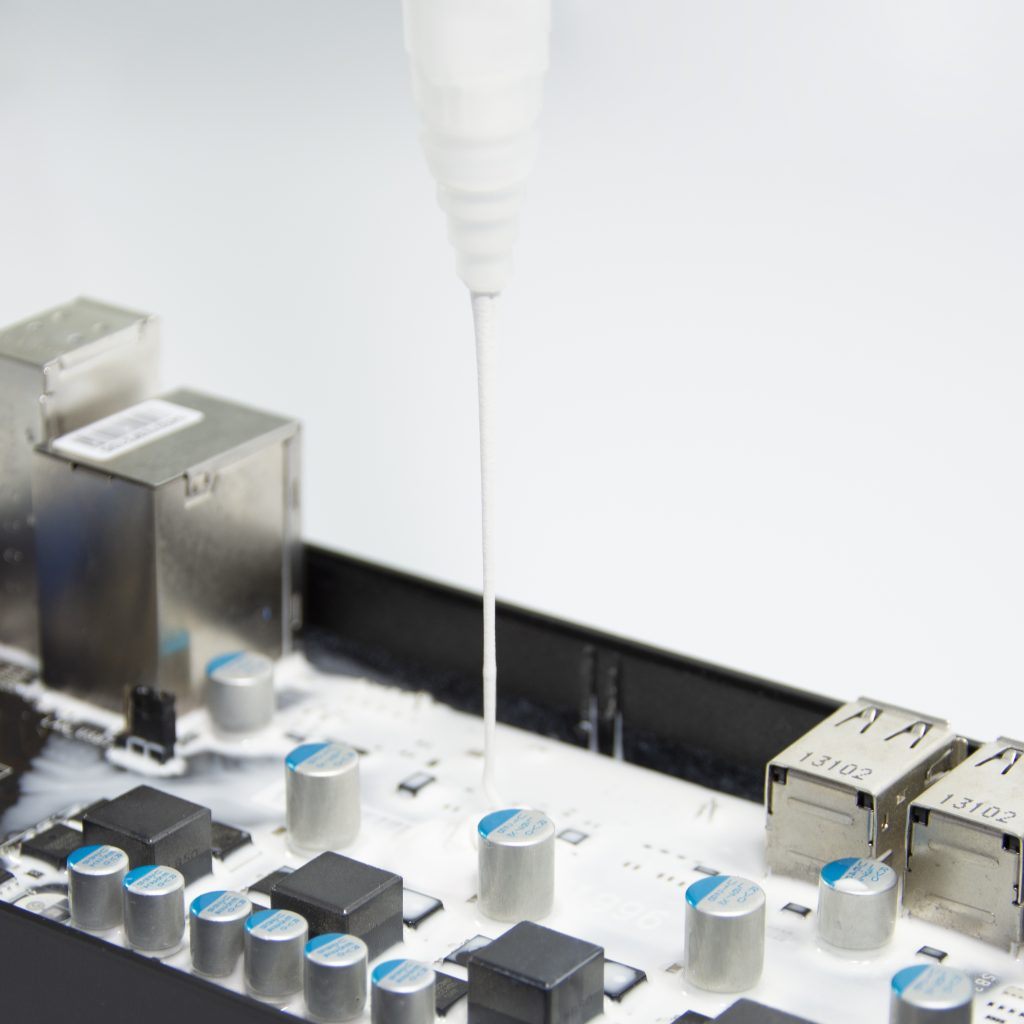

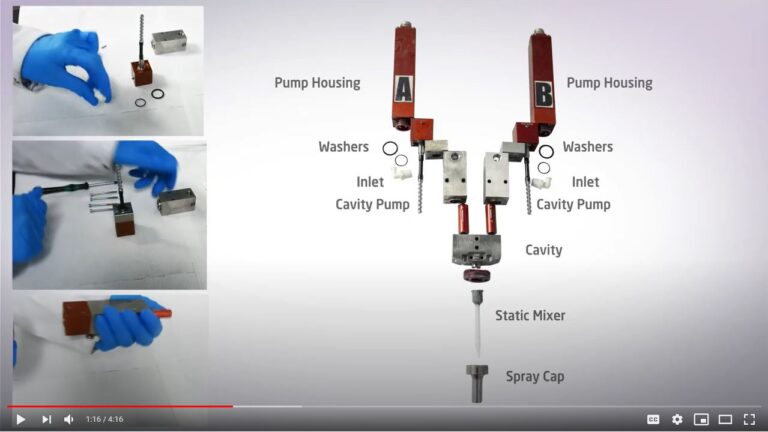

This will depend upon the size and geometry of the unit to be potted. For example, where medium to large size units are concerned, it is better to apply the resin in two or more locations allowing control of the flow of resin. If you are using a mobile dispensing head, I would suggest a layer of resin across the whole unit, rather than just depositing the required amount of resin in one location and allowing it to flow naturally throughout the unit.

The more components there are on a board (or in an assembly), and the more variable they are in terms of their geometry, the more complicated the flow patterns are likely to be. It may be possible to heat the resin to reduce its viscosity and improve the flow around a complicated component layout, but the downside of this will be a reduction in the resin’s working and cure times. Where air entrapment is a concern, it might be better to review the layout of the components to reduce the incidence of turbulent flows and the potential for air entrapment. Alternatively, you might want to consider the use of vacuum potting, which will ensure that the risk of air entrapment is as low as possible and that the resin will penetrate into all the available spaces.

How do I select the most appropriate resin for the job?

Beyond ensuring that your electronic assembly will meet its design criteria in use, choosing the correct resin for encapsulation purposes is possibly the second most critical aspect of the entire design process. It is important to understand where and how the finished unit is going to be utilised and what performance criteria are expected of it. It is best practice to draw up a list – in order of importance – of the standard operating conditions that the unit will be exposed to, and then to draw up a list of what the extremes of those operating conditions are likely to be.

Also of importance is the duration of time that the unit is exposed to the extremes of the expected operating conditions. There is a world of difference between specifying a chemically resistant resin that can withstand fully permanent immersion in, say, antifreeze, and one that only requires resistance to occasional splashes of antifreeze that are wiped clear after short periods of exposure.

In a similar vein, if an application reaches a maximum temperature of 150°C, but this only occurs once a day for a couple of minutes and the rest of the time the normal operating maximum is 90°C, then it is quite satisfactory to specify a resin with a normal operating temperature of, say, 120°C, as most modern materials will tolerate quite wide excursions for short periods.

Other application requirements to be considered might include flame retardancy, should UL certification be necessary; optical clarity and UV resistance, particularly in the case of LED lighting assemblies; opacity, which is often desired when protecting circuit designs from potential IP theft, and RF signal compatibility. It is always recommended to undertake some testing to confirm the suitability of the selected resin as every application is unique in terms of the operating parameters, conditions and the geometry of the unit.

What resin chemistries are available and how do they differ?

There are three major classes of resin chemistry: epoxy, polyurethane and silicone. Epoxy is the strongest and most chemically resistant of the three, but it is brittle, difficult if not impossible to remove for rework/repair and is typically limited to operating temperatures of between -40°C and +150°C. Epoxy resins however, offer excellent adhesion to a wide range of substrates.

Polyurethanes are both tough and flexible and are suitable for applications operating at lower temperatures. However, due to the limitations of polyurethane chemistry this type of resin is only suitable for applications reaching a maximum temperature of 110°C (though some can go to 130°C). The chemical resistance of a polyurethane resin is generally lower than that of an epoxy, but polyurethanes, dependent upon the chemical backbone, outperform epoxies in water splash or immersion and high humidity environments.

Polyurethane resins are typically used in marine applications, where water penetration resistance is critical, and for applications subject to a high level of physical or flexural stress, such as the potting of accelerometers, or sensors embedded in road surfaces. If large temperature swings are expected over a short timeframe, or prolonged temperature cycles, then the flexible nature of the resin is advantageous, as there is a low probability of stress cracking occurring.

Silicones have the widest possible operating temperature range (-50°C to +220°C) and when cured are the most flexible of the three resin chemistries. Their adhesion to certain substrates is poor, as is their chemical resistance, particularly with reference to acids, aromatics, ketones. However due to their aliphatic backbone they do offer excellent UV and colour stability, particularly for direct exterior applications. While they do tend to differ widely in terms of performance characteristics, all resin types have excellent electrical insulation properties across their respective temperature ranges.

Readers should bear in mind that the foregoing offers only general guidelines. Resin chemistries have advanced considerably in recent years and there are now resins from leading suppliers, such as Electrolube, that exhibit properties and performance criteria often well beyond the normal boundaries expected for that resin type.