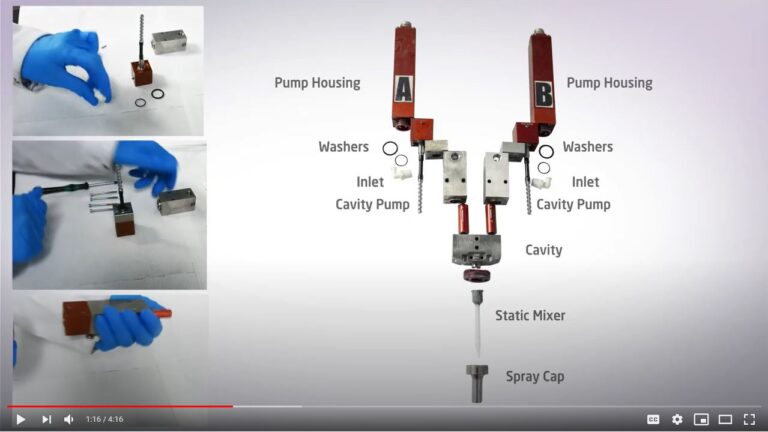

This video demonstrates how to best manually apply Electrolube TPM350 and TPM550. This process can also be achieved using an automated screen printing process.

For manual application of a phase change material using a screen, we recommend starting with a screen thread count of around 25 threads per cm. The thread count of the screen controls the thickness of the material applied and may need to be adjusted to suit your particular application.

Lay the cleaned heat sink or substrate, face up on a flat work surface. Place the screen evenly over the surface and apply a thick line of phase change material at the far end of the screen using a spatula.

Using a squeegee that is wider than the substrate, slowly and carefully drag the phase change material over the surface, ensuring all areas are completely covered. Apply high pressure to the squeegee when in use and only pass over the surface once.

Gently lift the screen, slowly applying pressure so that you can see the screen separating from the surface. Do not lift the screen off quickly or unevenly as this may affect the distribution of the phase change material left on the substrate.

Once removed, you should be left with a uniform layer of phase change material on the substrate. Follow the instructions given on the technical data sheet to ensure any solvent present is evaporated before assembly.

To clean the screen after use, wipe off any excess with a dry cloth and then clean with Electrolube SSS – Screen and Stencil Solvent.