In my last column, we looked at how to select the appropriate resin for your requirement, bearing in mind that correct product selection is affected by the physical constraints of the board or area to be covered, as well as other issues. For this month’s column, I am going to concentrate on protecting sensitive components and take a more indepth look at flexible resins, their reworkability and some of the common problematic consequences that you may encounter. Potting compounds play an important role in the electronics industry, where they serve to protect sensitive components from chemicals, moisture, dust and damage, but their selection can baffle many, so in a Q&A format, let’s explore some frequently asked questions in more detail.

What are the key considerations when selecting a resin for potting sensitive components?

There are many important factors to consider when choosing a suitable resin to pot sensitive components. Firstly, you need to determine what temperature range is expected and look at the design, shape and dimensions of the components. For instance, does a component have long thin legs that could be snapped off? It is also important to determine how large a volume of resin will be necessary to enable the degree of protection required.

It is also advisable to check the compatilibilty of the resin with the housing material. In the majority of cases, there aren’t any compatibility issues but it’s worth checking just to be safe.

Examine how dense the component layout is on the board and consider how well the resin will flow across the board. It is worth noting that lower viscosity resins flow better, however, a thixotropic resin might afford better control to obtain the desired coverage. Does the resin need to flow under components and, conversely, should it not flow in certain areas? Also consider whether the resin needs to be flame retardant and if so, to what approval level?

The end-use environment is a key factor not to be overlooked. Consider what environment the finished unit will be exposed to as this may be harsh, which will also affect which resin is most suitable. In turn, this will also define whether the resin needs to provide primary or secondary protection against it. You might also need to protect electrical or electronic components that are likely to come into contact with chemicals, including acids, alkalis, solvents and a whole raft of other substances that pose a threat to delicate circuits and components. Chemical resistance is very much the province of epoxy resins, though some of the tougher polyurethane products as well as some silicone based formulations – will provide a degree of protection, particularly against moisture/water ingress. Epoxy resin products are available to protect electrical/electronic units that undergo frequent or permanent immersion in solvents such as diesel fuel, leaded and unleaded petrol and cellulose thinners.

Can resins be dug out/reworked if necessary?

The simple answer to this is yes, there are specialised dig-outable resins available for use. These are primarily aimed at development and prototyping projects where easy access to components is required. They generally have poor chemical resistance and physical properties, particularly in terms of strength and toughness. However, in the case of more general resins, it is possible to remove cured resin from around components and areas on a PCB, but these require either the use of a solvent or cutting away the resin from the area of interest. The hole can then be refilled with some more freshly mixed resin, but this then leads to a potential weak spot in the resin coverage as chemicals and water could penetrate through the resin interface. Similarly, thermal cycling/shock could cause the interface to weaken and become exposed. Both polyurethane and silicone resins are more easily removed for rework purposes, and special solvents are available to assist with this process.

What are the possible implications of a resin being unable to maintain flexibility at low temperatures?

Normally, the main reason for a resin to lose its flexibility is due to brittleness. This can be due to a number of factors, but at low temperatures the most likely reason is because the resin approaches or passes through its glass transition temperature (Tg). This is the temperature at which a resin goes from a brittle or glassy state to a rubbery state. The effect upon the components/PCB is that they will experience increased levels of physical stress, which might lead to components being broken and/or legs being snapped. In worst case scenarios, even the PCB itself could be broken.

What are the consequences of leaving contaminants on the PCB before encapsulating?

Prepare for contaminant warfare! If a resin is applied to a PCB that is still covered by contaminants, then the resin will adhere to the surface of the contaminant rather than the PCB substrate or the surface of the components. Therefore, if there is a failure of adhesion between either the resin and the contaminant, or the substrate and the contaminant, then this will introduce a point of weakness in the resin-substrate interface, which could allow other contaminants to attack the PCB/components.

The contaminants may directly attack the PCB/components or induce an attack, for example if a piece of solder is left and bridges across the copper tracks or across two component legs, and is then covered in resin, this increases the severity of the attack and prevents removal of the contaminant. Ultimately, leaving contaminants on a PCB prior to encapsulation could lead to shorting and will result in the premature failure of the unit.

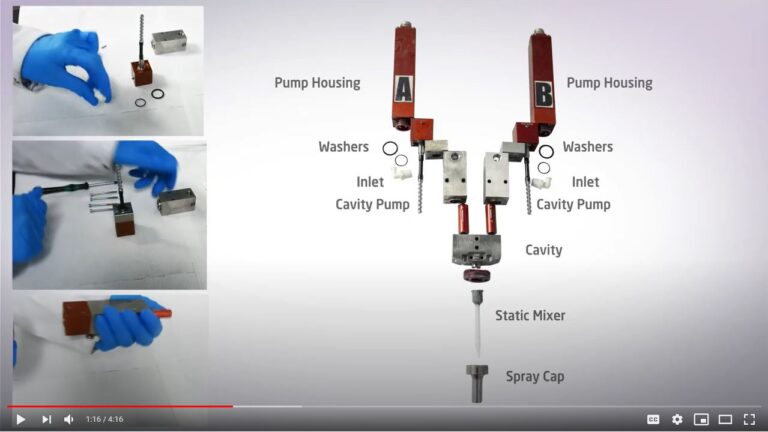

What are the consequences of taking in too much air when the resin is being mixed?

Taking in too much air during mixing can cause a whole world of pain, however, this is a very common problem. Incorporation of air into the resin is to be avoided at all costs as excessive air can lead to a lower density material being created. In the case of mixing machines that dispense by volume, this means that there is insufficient resin being applied once the air has been released during the pouring and initial curing time of the resin. If the air is trapped in the final cured resin, this can lead to a premature failure of the resin due to voids being created, which are weak spots, particularly for thermal and physical shock. The actual resin thickness applied will be lower than it appears, resulting in potentially lower performance and a premature unit failure.

If the cured resin containing entrapped air is subjected to pressure or vacuum, the resin could rupture, exposing the PCB and components to the atmosphere. If the void created by the trapped air is directly next to a component or copper tracks, it acts as a concentration point for static charges to be built up, which in certain applications can reach an energy level that is powerful enough to punch its way through the resin layers to ground itself and cause a short circuit. I can’t emphasise enough how important it is to give very careful attention to the prevention of air entrapment.

Conclusion

When it comes to discussing the choice, applications and protective properties of resins, there’s a great deal more we need to cover. In my forthcoming columns on resin systems, I hope to provide some useful tips and design advice that will help you achieve the highest level of circuit protection, whilst guiding you through the pitfalls and pain-points that are best avoided to prevent shorting and premature unit failure. At Electrolube, we talk solutions every day, so if you have any questions about encapsulation resins, please do talk to us.