Estimated Read Time: 1100 words = 4 mins

So far in my resin blogs we’ve looked at the various reasons for circuit potting and encapsulation using resins, outlined the various resin properties and how they relate to particular types of circuit protection, seen how to apply these resins in a production environment by deciding on which mixing and application techniques are appropriate to specific production needs, and finally, how best to achieve a satisfactory cure. But, I hear you ask, which type of resin is best for my project and production methods? How are my choices affected by the physical constraints of the board or area to be covered? What resins are suitable for rework? These and other issues I hope to cover in this latest blog.

Choosing Your Chemistry

Basically, you have a choice of three main types of resin: epoxy, polyurethane and silicone. Each has distinctive properties and your choice will be guided by how these properties can be exploited to meet your particular production circumstances and application needs. Let’s first take a look at production volumes; are you prototyping, delivering a short production run or manufacturing on a much larger scale? Your answers to these questions will determine whether you use manual or machine-based application methods – and this will pose a further question:

Which Resin Types are Compatible with Which Application Techniques?

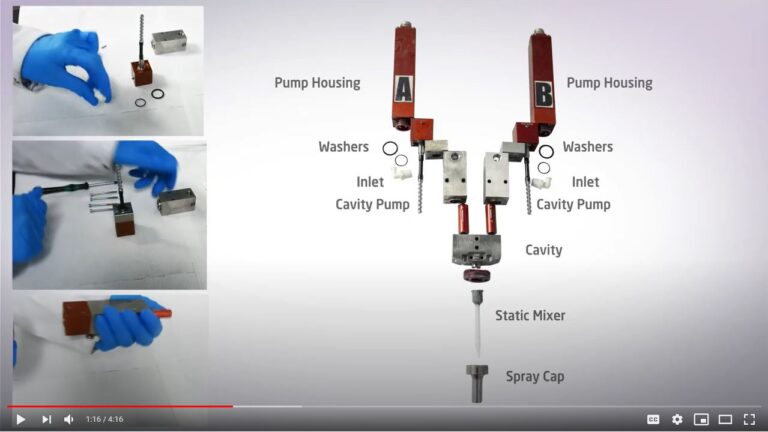

For example, if you are potting prototypes or small volume runs you will most likely use manual methods, while much larger volume runs will best be served by automated, machine-based mixing and dispensing systems. Should you be looking to work up from the prototype stage to a full production run, then the differences between manual and machine mixing and dispensing will have to be taken into account when choosing your resin.

When mixing and dispensing manually, a longer useable life and gel time will generally be required compared with machine mixing, which is a faster process that doesn’t necessarily need these properties. The process could involve the use of two different resins with different mixed properties, but having similar cured properties in order to take full advantage of the two different mixing conditions. Useable life is defined as the time that the mixed resin can flow and is still workable; the gel time is the interval between mixing and the point at which the resin has just set and cannot flow. In the latter state, the resin is still relatively soft and can often be re-shaped by applying slight pressure. However, note that the larger the volume of mixed resin, the shorter the useable life and gel time.

If a rigid to semi-rigid encapsulation is acceptable, then the slower curing rate of a two-part epoxy resin would provide the desired longer useable life and gel time for manual mixing. Epoxy resins are also suitable for machine dispensing but caution should be exercised if the resin contains abrasive fillers as these will accelerate the wear of dispensing equipment. To mitigate this problem, epoxy resins are available without fillers. Should a more flexible cured finish be required, then polyurethane or silicone based resins would be suitable alternatives to epoxies.

Unlike epoxy based resins, which tend to heat up on curing (they exhibit a high exotherm), two-part polyurethane resins – even the faster-curing versions – are not exothermic, which may be advantageous when potting delicate components. While silicone resins tend to be less popular than either epoxy or polyurethane resins, they are highly flexible on cure and they tolerate continuous high operating temperatures – often in excess of 180°C.

How do you Want it to be Applied?

When the resin is mixed, next comes the question: how do you want it to be applied? If the parts of the circuit to be coated are defined, discrete areas, then generally either a dam-and-fill system is employed to isolate the areas that need to be potted or a more thixotropic resin can be used. Some single-part epoxies and especially silicone resins have these advantageous thixotropic properties.

On the other hand, if an entire board needs to be covered, then resins with good flow characteristics should be used as the resin will be designed to flow from a dispensing point to cover the board. Most two-part epoxy resins – even those containing fillers – are not only easily mixed but can flow between components and devices with limited spacing.

But How Much Resin Should You Apply?

As a general rule of thumb the amount of resin that needs to be applied has to be sufficient to cover the top of the highest component of the board, and the thickness of the resin layer must provide the desired level of protection. While most customers will determine the minimum thickness of resin layers for their particular applications by trial and error, the relevant technical data sheet will provide good guidance, and consulting your supplier will often help resolve a problem.

A Note Here About Colour:

Optically clear resins may be desirable for applications such as LED lighting fixtures, as the cured resin will obviously need to retain its clarity for the life of the unit. Colourless resins are also useful for prototyping applications as the encapsulated components are easily viewed during and after environmental and mechanical testing. On the other hand, coloured/opaque potting and encapsulation resins conceal what lies beneath the encapsulant surface, providing an effective foil against counterfeiters or those wishing to copy a circuit layout, helping you to protect your intellectual property.

On the subject of prototype boards and systems, it is often desirable to be able to inspect the board and identify and remove failed components for inspection and replacement. There is a range of resins which are more suitable for use when reworking or repair may be necessary, as well as a range of products designed to allow the removal of cured resin from the board. Both polyurethane and silicone resins are more easily removed for rework purposes, and special solvents are available to assist with this process.

As previously mentioned, technical data sheets can be a great help when you embark on a new production schedule with new components and resins, but if you foresee any problems with matching resin types to your production procedures that are not easily resolved by studying the literature, be sure to contact your supplier’s technical support team for further advice. Like us, at Electrolube, we relish a challenge!

Next time, I shall be taking an in-depth look at some of the most frequently asked questions we get asked as resin experts and exploring options in response to these enquiries.