Electronics for military applications are expected to operate first-time, every time in some of the most hostile and demanding environments. Military programmes are often designed to run over several decades, with hardware likely to be updated several times over the programme’s duration. Similarly, most aerospace electronics will be compromised by harsh operating environments; significant amounts of vibration, often extreme variations in operating temperature, as well as the risks of exposure to chemicals, de-icing fluids and the like, will all take their toll unless adequately protected. Commercial and military aerospace applications, too, will typically have multi-decade programme lifetimes and the hardware will usually be upgraded several times during its service life. Long term protection of military and aerospace electronics is thus important.

Electrolube is an ISO 14001 accredited, UK based company that has been manufacturing high-specification, formulated chemical products for electronics manufacturers since 1941. Serving a plethora of industries including the aerospace, military, marine, automotive and telecoms industries, Electrolube provides both bespoke and ‘off-the-shelf’ products, including thermal management formulations, conformal coatings, encapsulation resins, contact lubricants and aqueous and solvent-based cleaning materials, as well as more general maintenance and service aids.

Electrolube has extensive experience of working within these sectors, its relevant systems and product formulations being fully compliant with industry standards, including MIL-STD 810 (environmental) and MIL- 1-46058-C, now superseded by IPC-CC-830B, IEC-61086 and UL746 (conformal coating).

Electrolube’s primary and secondary conformal coating protection systems, include products based on acrylic, urethane, silicone, epoxy and parylene formulations, offering features that give enhanced protection against certain specified environmental conditions (high humidity, condensation risk, high operating temperatures, etc.), which meet appropriate standards such as US MIL-1-46058C, UL746, British Ministry of Defence DEF-STAN 59/47 Issue 4 and UL746CQMJU2.

However, it’s not just about extending the lifetime of electronic systems in storage or in duty, but addressing all concerns regarding their reliability and performance; thermal management is key to achieving this. The development of aerospace and defence electronic systems is driving significant increases in power densities, with the result that thermal management has become a significant challenge for suppliers of hardware to this sector.

Electrolube can provide a particularly versatile range of products that address these thermal management issues, providing effective heat dissipation and preventing device failure as a result of elevated operational temperatures.

Most electrical components are low powered devices that produce negligible amounts of thermal energy; however, there are also many devices – such as CPUs, power diodes, power transistors and so on – that produce significant amounts of heat and it is important that this heat is removed from the device quickly and efficiently to ensure optimal performance, and to prevent premature component failure. This is somewhat exacerbated by the trend for product miniaturisation and the use of compact, higher powered devices, which place greater demands on thermal management systems.

Heatsinks are commonly deployed to conduct and radiate heat from high power electronic components, the device and heatsink – usually solid substrates – being mechanically bolted together. Ideally, the surfaces of these substrates should be perfectly smooth, but this is not always possible and, as a result, air gaps will be present at the interface. Air is an extremely poor thermal conductor (0.024W/mK), and so the interface between the heat-sink and device will compromise heat transfer efficiency.

To counter this problem, these air-gaps need to be filled with a material that will produce a significantly improved thermal interface between the two substrates. This material can be a thermal paste, an adhesive, a room temperature vulcanized (RTV) silicone, thermal-pad, or some other thermally conductive medium. A good tip when introducing the interface material is to apply the minimum amount of product necessary to fill the air gaps, thus keeping the thermal resistance as low as possible. Applying too much material will increase the thermal resistance of the interface, resulting in a reduction in performance.

In most cases, due to the increased filler content, high thermal conductivity means that the material will generally have a high viscosity. As a result, the possibility of air entrapment needs to be considered when applying the product. A highly viscous material may increase the risk of air entrapment, reducing the thermal conductivity performance; in such cases, a lower viscosity material might be a more appropriate choice.

Before we take a look at the thermal management products available from Electrolube, it is worth considering the various methods used to measure the thermal conductivity when qualifying heat-transfer products.

Some techniques only measure the sum of the material’s thermal resistance and the material/instrument contact resistance. Electrolube uses a version of the heat-flow method that measures both of these values separately. Values quoted using this heat-flow method are closer to the materials ‘true’ thermal conductivity. Alternative methods that do not separate the material’s thermal resistance and the material/instrument contact resistance may look more impressive, but these higher readings are less accurate. Electrolube’s in-house testing equipment is state of the art, and ensures all products reach the market with the reassuring capability to deliver reliability and performance.

Electrolube’s thermal product range

Electrolube provides thermal management interface solutions in the form of thermal pastes, RTV silicones, epoxy adhesives, and epoxy/polyurethane-based potting compounds.

Thermally conductive pastes consist of thermally conductive fillers in a carrier fluid, the former being a blend of one or more mineral fillers depending on the desired thermal properties, and the latter a silicone or non-silicone based medium.

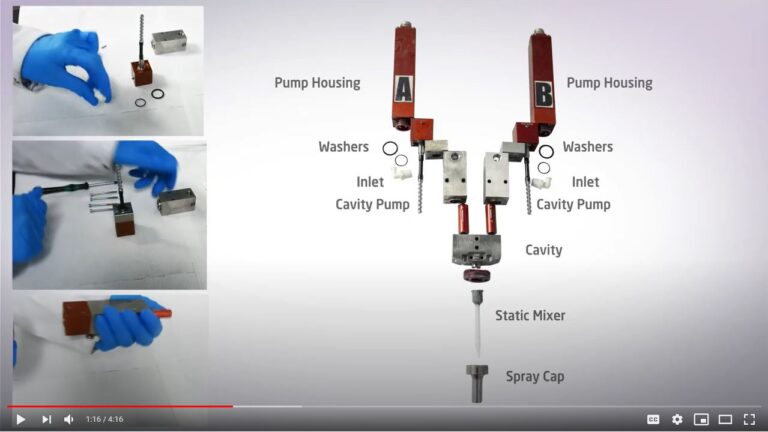

Thermal pastes do not cure and so they offer the best solution there is; the capacity for rework during the life of the component. A thin layer of paste should be applied between the device and the heat-sink to fill the air-gaps and improve the contact. Application can be via stencil printing, screen printing, automatic dispensing equipment, or even using an aerosol spray product such as Electrolube’s 100 percent ozone-friendly HTCA non-silicone formulation.

Silicone based thermal paste products usually deliver lower oil bleed and evaporation weight loss compared with their non-silicone counterparts, as well as offering a higher upper temperature limit, which can be in excess of 200˚C. However, there are applications where silicones may be unsuitable – when devices are sensitive to silicone contamination, for example.

Electrolube’s silicone thermal pastes include the HTS and HTSP. HTS is the standard product, offering an operational temperature range of -50°C to +200°C and a thermal conductivity of 0.90W/mK, while HTSP is a higher conductivity version (3.0W/mK) for critical applications requiring a high level of thermal transfer performance.

Electrolube’s two non-silicone thermal pastes called HTCX and HTCPX – the ‘X’ suffix denoting ‘Xtra’ or higher performing versions of HTC and HTCP – provide increased thermal conductivity (1.35W/mK for HTCX and an impressive 3.40W/mK for HTCPX), lower oil-bleed and lower evaporation weight loss. In fact, the ‘Xtra’ versions deliver oil-bleed and evaporation weight loss performances as good as Electrolube’s silicone-based pastes.

For certain applications it may be desirable to use a product that cures into a solid, which may or may not require bonding two surfaces together. Electrolube offers three types of product that fall into this category: TBS, TCOR and TCER.

TBS (Thermal Bonding System) is a two-part, high strength epoxy adhesive designed to bond a heat sink to the component. In addition to the mineral fillers, the adhesive contains small glass beads of controlled diameter: these allow for a set thickness (equal to the diameter of the beads) to be achieved in order to provide optimal performance.

TCOR and TCER are Electrolube’s neutral cure, silicone RTV products. TCOR is an oxime cure RTV, and TCER is an ethanol cure version. TCER has the advantage that it is very low in viscosity and higher in thermal conductivity (2.20W/mK) compared to TCOR (1.80 W/mK); however, TCOR exhibits improved bond-strength properties.

For certain types of heat generating circuitry such as power supplies, it may be beneficial to encapsulate the device in a heat-sink enclosure using a thermally conductive potting compound. Electrolube produces a variety of two-part thermally conductive encapsulation products based on epoxy and polyurethane technologies.

One of our longest standing thermally conductive resins is ER2074; a highly-filled epoxy resin possessing high thermal conductivity (1.26 W/mK), but as a result is high in viscosity (16,700cPs). ER2183 is a lower viscosity version of ER2074 (5,000cPs). The reduced filler content required to achieve this viscosity has little effect on the thermal conductivity performance: ER2183 is 70 percent lower in viscosity, but only exhibits a 13 percent decrease in thermal conductivity as a result (1.1 W/mK).

UR5097 is a polyurethane potting compound that possesses a similar viscosity to ER2183 (6,000cPs) and good thermal conductivity (0.65W/mK); however, it also has the added benefit of UL94-V0 certification – particularly useful for applications requiring a thermally conductive, flame retardant resin.

The recent revision and expansion of Electrolube’s thermal product range highlights the company’s dedication to providing high performance products of exceptional quality. And if no off-the-shelf product meets the needs of a particular application, depending upon volumes, the technical team will formulate one that does. This commitment ensures that customers have the products for today’s needs, as well as the technologies of tomorrow.